- Home

- Solar Heating

- Solar Collector

- Heat Pipe Solar Collector

Heat Pipe Solar Collector

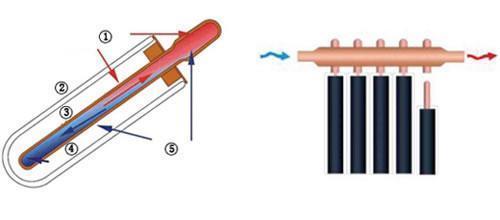

The heat pipe solar collector is generally connected to the existing heating supply system. The selective absorption layer coated at the inside of the evacuated tubes converts the solar energy into heat energy, and then the heat is transferred to the heat pipes by the aluminium fins of the solar collecting system.

In the heat pipe, the liquid will be changed into vapour and rise to the condenser installed on the heat pipe solar collector. Through heat exchanger, vapour will be turned into liquid and returns to the bottom of the heat pipe. The heat transfer to the liquid (anti-freezing liquid or water) is conducted through the copper pipe of the solar evacuated tube collector. As long as the heat pipe solar collector is heated by the solar energy, continuous heat circulation can be achieved.

1. Hot vapour rises to top of the heat pipe

2. Evacuated tube

3. Copper heat pipe

4. Non-toxic liquid

5. The vapor is liquefied and returns to the bottom of pipe for recirculation

Material of the Heat Pipe Solar Collector

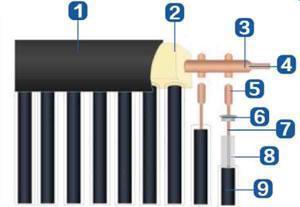

1. Main casing: anodized aluminum alloy

2. Header pipe: copper

3. Heat pipe: TU1 copper

4. Insulating layer: glass fabric

5. Holder: galvanized plate

6. Evacuated tube: ALN/AIN-SS/Cu

1. Main casing

2. Insulating layer

3. Header pipe

4. Connector

5. Heat pipe condensing end

6. Seal ring

7. Heat pipe

8. Aluminum fin

9. Evacuated tube

Features

1. The diameter of the heat pipe condensing end is 24mm, ensuring optimal heat exchange capacity.

2. The header pipe is designed with big size. So it has small flow

resistance, making the product suitable for commercial solar water

heating project.

3. The copper material for making the heat pipe comes with the purity up to 99.97%.

4. The heat collecting efficiency is 73.5%.

5. The heat pipe solar collector is Keymark certified.

| Models | Vacuum Tuber | Daily Output (Liter/Day/60°C) | Gross Area | Size(mm) | Qty (set) | ||||

| A | B | C | D | 20ft | 40ft high cube | ||||

| HRJ7-10/1.8 | Φ58×1800×10pcs | 90-100 | 1.52 | 786 | 1950 | 648 | 150 | 164 | 329 |

| HRJ7-15/1.8 | Φ58×1800×15pcs | 140-150 | 2.22 | 1146 | 1950 | 1008 | 150 | 104 | 216 |

| HRJ7-20/1.8 | Φ58×1800×20pcs | 180-210 | 2.92 | 1506 | 1950 | 1368 | 150 | 70 | 130 |

| HRJ7-25/1.8 | Φ58×1800×25pcs | 230-260 | 3.73 | 1866 | 1950 | 1728 | 150 | 61 | 130 |

| HRJ7-30/1.8 | Φ58×1800×30pcs | 280-300 | 4.32 | 2226 | 1950 | 2088 | 150 | 50 | 109 |

Other Related Information

Payment term: T/T or L/C

Delivery time: 20 days

Minimum order: 1 set

Shipping port: Tianjin

Brand: Himin or OEM

Place of origin: China

Why Us

Quality Control for Heat Pipe Solar Collector

1. Test on Low Temperature Resistance Performance

Put the heat pipe in the refrigerator with the temperature of -30°C and freeze it for 1 hour. Then, move the heat pipe to the environment with room temperature or put it in the hot water for unfreezing. Little variation on the performance and the shape can be found, upon 20 times repeated testing within 48 hours.

2. Isothermality Inspection

The ambient temperature for isothermality inspection shall be from 15°C to 30°C. Immerse 1/3 to 1/2 of the heat pipe into the water with constant temperature of 70°C±2°C for heating, and leave the other end exposed in the air for cooling. The inserting angle shall be from 30° to 60°. One minute later, test the temperature at the two marked points with calibrated temperature measurer. The result is show as follows.

Heat tube length≥1.5m, 丨Tb-Ta丨≤3.0°C

Heat tube length≤1.m, 丨Tb-Ta丨≤2.0°C

3. Anti-aging Performance Test

The anti-aging performance test is conducted in the high temperature aging oven. After 50,000 hours’ aging with the temperature of 250°C, the performance degradation of the heat pipe for the heat pipe solar collector is less than 5%.

4. Advanced Production Technology

In 2010, our company invested RMB 40 million for the construction of the first gravity-assisted heat pipe production line in China. The annual output reaches up to 2 million.

1). Cleaning Technology

A clean internal surface is the prerequisite for the production of high performance heat pipe. To ensure the first class quality, the inner and outer wall of the heat pipe are processed with 8 procedures, such as pre-cleaning, cleaning, passivation, drying, etc.

Our company introduces automatic copper reducer cleaning line, which is the first full automatic ultrasonic cleaning line all over the world for the production of heat pipe solar collector.

Cleaning Technology

The reducing heat pipe is welded with high-frequency induction welding technology. The overlap welding of the evaporation and the condensation section for the heat pipe increases the face of weld. In addition, the silver-based soldering material with optimal mechanical property and flowing property ensures the outstanding impact resistance and air tightness of the heat pipe solar collector.

3) High-temperature Degassing Technology

We are the technology pioneer for the high-temperature annealing degassing line. The gas attached to the surface of the heat pipe is removed by high temperature, realizing stress elimination of the face of weld. The avoidance of the permanent permeation of the non-condensable gas effectively guarantees the long service life of the heat pipe solar collector.

5) Second Degassing Technology

In the heat pipe production line, we specially employ second degassing technology to eliminate the non-condensable gas inside the heat pipe, on the premise of sufficient working medium filling weight. The technology helps improve isothermal efficiency of the heat pipe and achieve zero temperature difference. In addition, the problem caused by the uncontrollability of the working medium filling weight for second degassing has been solved, effectively improving the heat transfer efficiency of the heat pipe. This technology has been granted the national patent for invention.

Heat pipe solar collector project in Tibet